Y16 series Circular Electrical Connector

Environmental Specifications

| Operating temperature | -55 to +125°C | Sinusoidal Vibration | 10 ~ 50 Hz, single amplitude 1.5 mm

(Z type: 2.0 mm) 50 Hz ~ 2000 Hz, 196 m/s2 |

| Working pressure | 101.3kPa ~ 6.67Pa | ||

| Relative humidity | 40± 2℃ @ 92% ~ 98% | Fungus | GJB150.10A, class 2 |

| Mechanical life | 1000 cycles

500 cycles (Y16N) |

Shock | 392 m/s2, 10 ms 980 m/s2, 3 ms |

| Rain fall | 5 mm/min | Hermetic Seal | Ordinary Seal≥ 98 KPa Glass sintering seal ≤1×10-5 Pa.L/s |

Electrical specifications

- Contact resistance and rated current

| Contact diameter (mm) | 1 | 1.3 | 1.5 | 2.5 | 3 | 3.5 | 5 |

| Rated Current (A) | 5 | 7 | 10 | 25 | 30 | 60 | 75 |

| Contact resistance (mΩ) Φ1.0 | ≤ 5 | ≤ 4 | ≤ 3 | ≤ 1 | ≤ 1 | ≤ 1 | ≤ 1 |

- Rated voltage, withstand voltage and insulation resistance

| Working Environment | Withstand Voltage (Vrms) | Insulation Resistance (MΩ) |

| Normal Temperature and pressure | 1500 2500 (Class A products) |

≥ 1000 |

| High temperature and humidity | 500 | ≥ 20 |

| High temperature | — | ≥ 500 |

| Low air pressure: 4.39kpa | 150 | — |

Mechanical specifications

| Housing Material | Copper alloy | Insulator Material | Thermoplastic |

| Housing Plating | Electroless Nickel plating | Contact material/ plating | Copper alloy/Gold plating |

Order mark

| Y16 | P | -24 | 30 | Z | J | 10 | a | |

Series No.

|

Y16 | |||||||

Class

|

P | |||||||

Shell number

|

24 | |||||||

Contact arrangement

|

30 | |||||||

Connector type

|

Z | |||||||

Contact type

|

J | |||||||

Mounting type

|

10 | |||||||

Headstock plug-in anti-loose

|

a |

Note: The Shell number is for plugs only (Class E is for sockets only), and Class N products currently only have 24# housings.

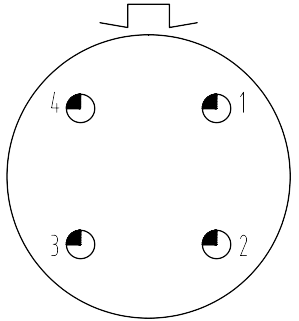

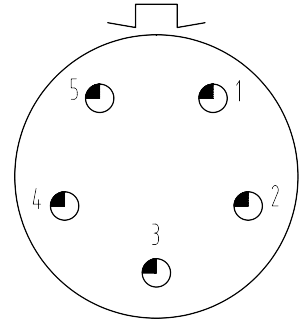

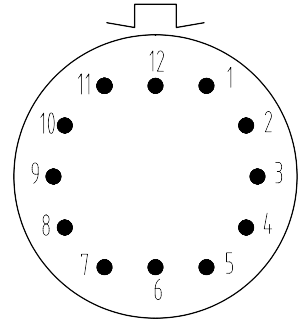

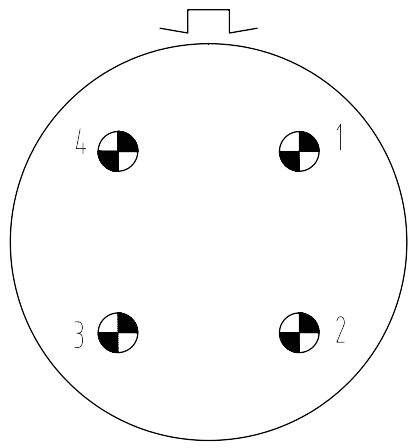

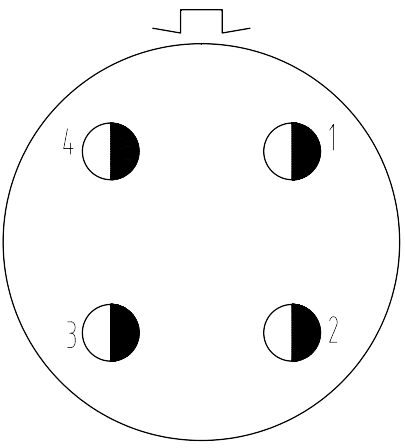

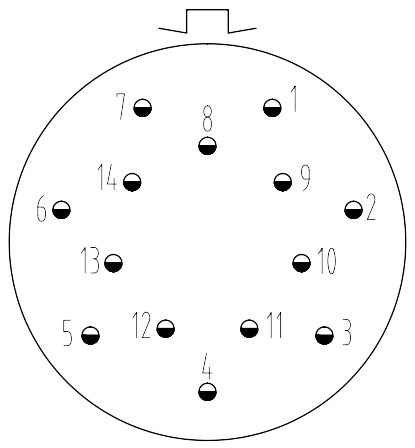

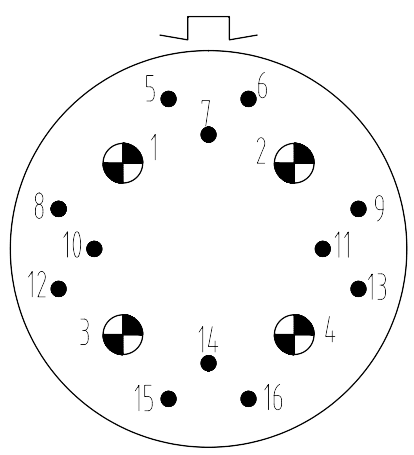

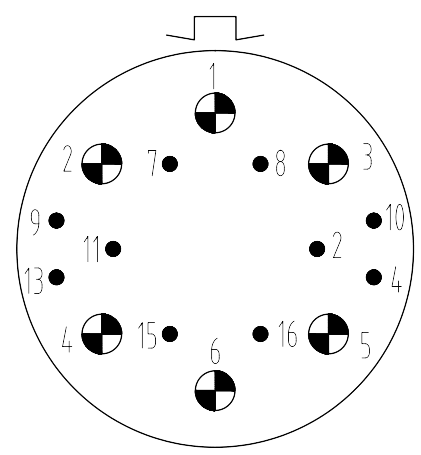

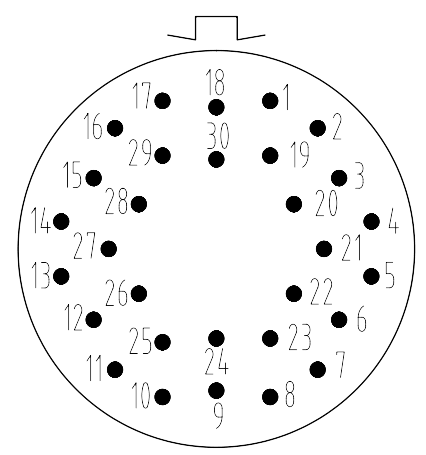

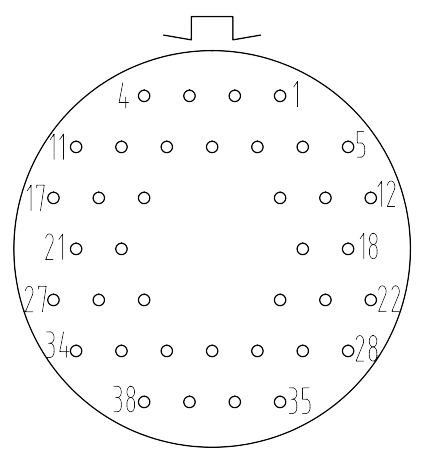

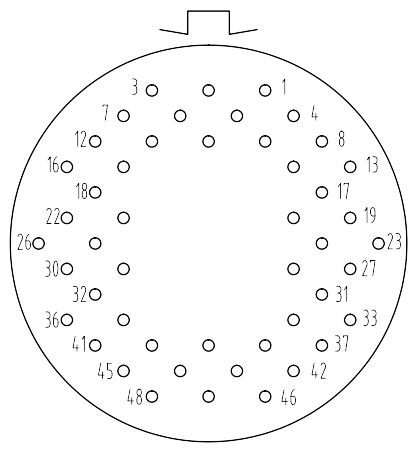

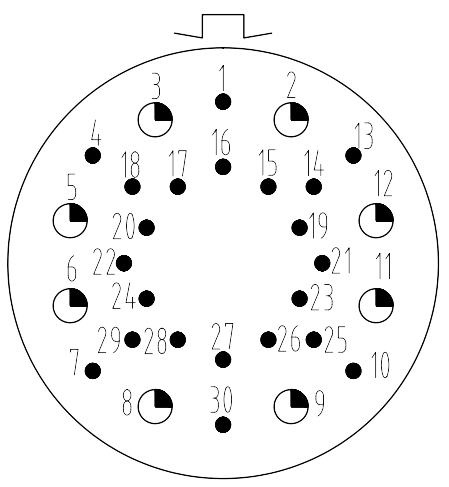

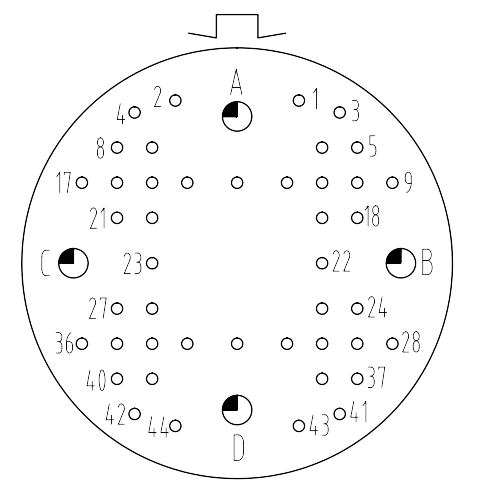

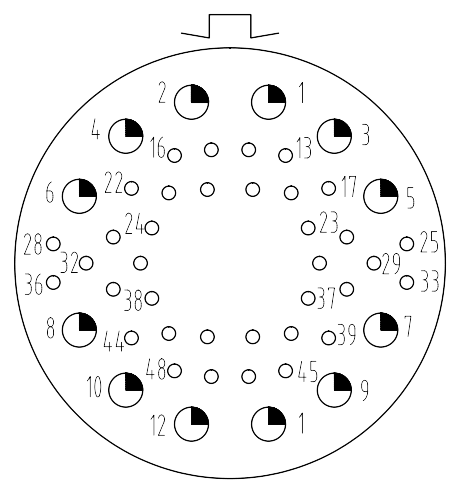

Contact arrangement

| Contact Spec | ||||||

|

|

|

|

|||

| 1 | 1.3 | 1.5 | 2.5 | 3 | 3.5 | 5 |

| 18 |  |

|

|

| 1804 | 1805 | 1812 | |

| 24 |  |

|

|

| 2404 | 2404I | 2414 | |

|

|

|

|

| 2416 | 2416I | 2430 | |

|

|

||

| 2438 | 2448 | ||

| 30 |  |

|

|

| 3048 | 3048I | 3030 |

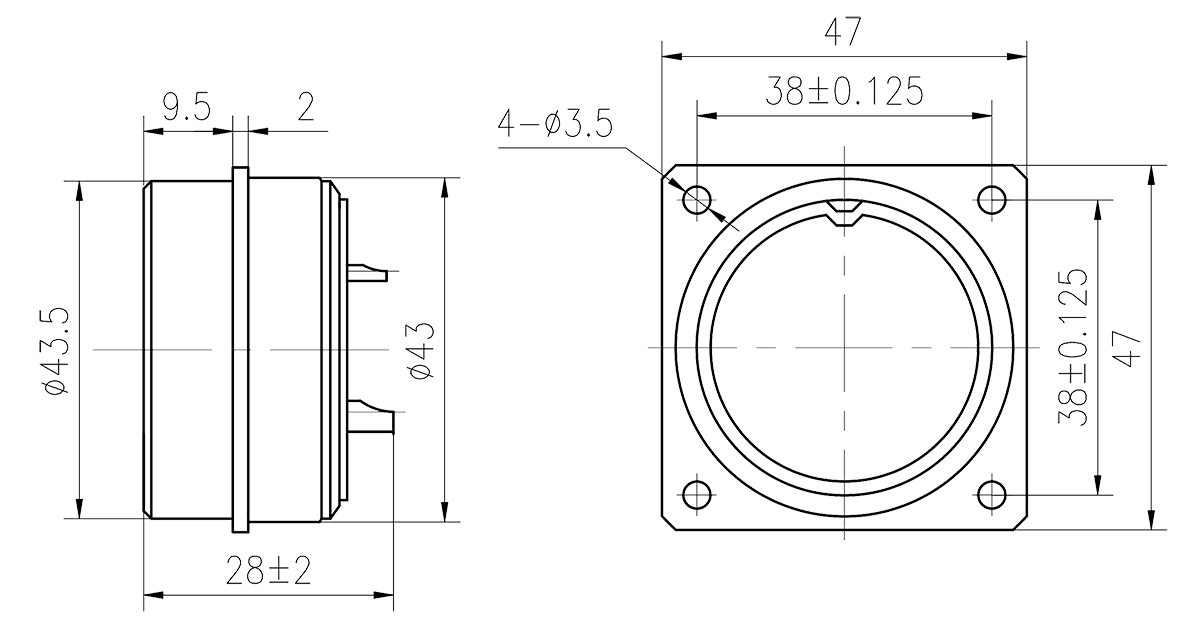

Drawings

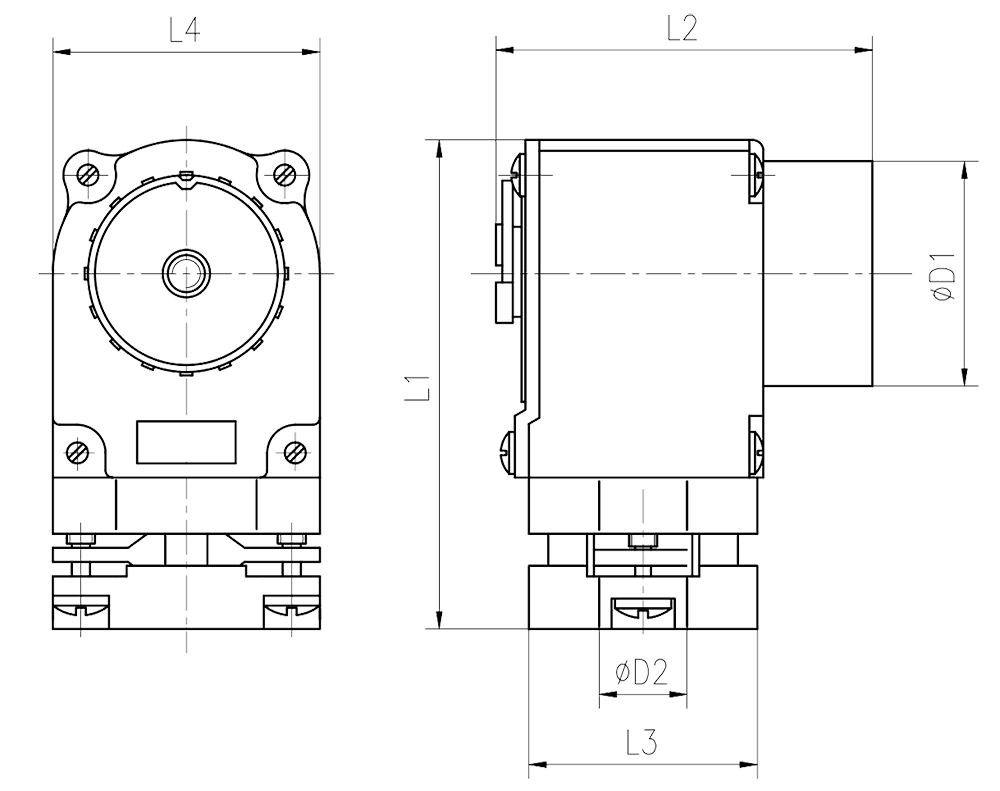

- Plug

|

||||||||||

| Specification No. | L3 | L4 | D1 | L1 | L2 | D2 | ||||

| P | H | P | H | P | H | |||||

| 18 | 25 | 31.5 | 38 | 28 | 69.5±3 | 42±2 | 48.5±2 | 12 | 12.5 | |

| 24 | 2404

2404I 2414 2430 2438 2448 |

31.5 | 38 | 48 | 38 | 71.5±3 | 48.5±2 | 55±2 | 18 | 22 |

| 2416

2416I |

38 | 58.5 | 48 | 38 | 77.5±3 | 55±2 | 75.5±2 | 22 | 23.5 | |

| 30 | 57 | 51 | 41 | 77.5±3 | 55±2 | 26.5 | ||||

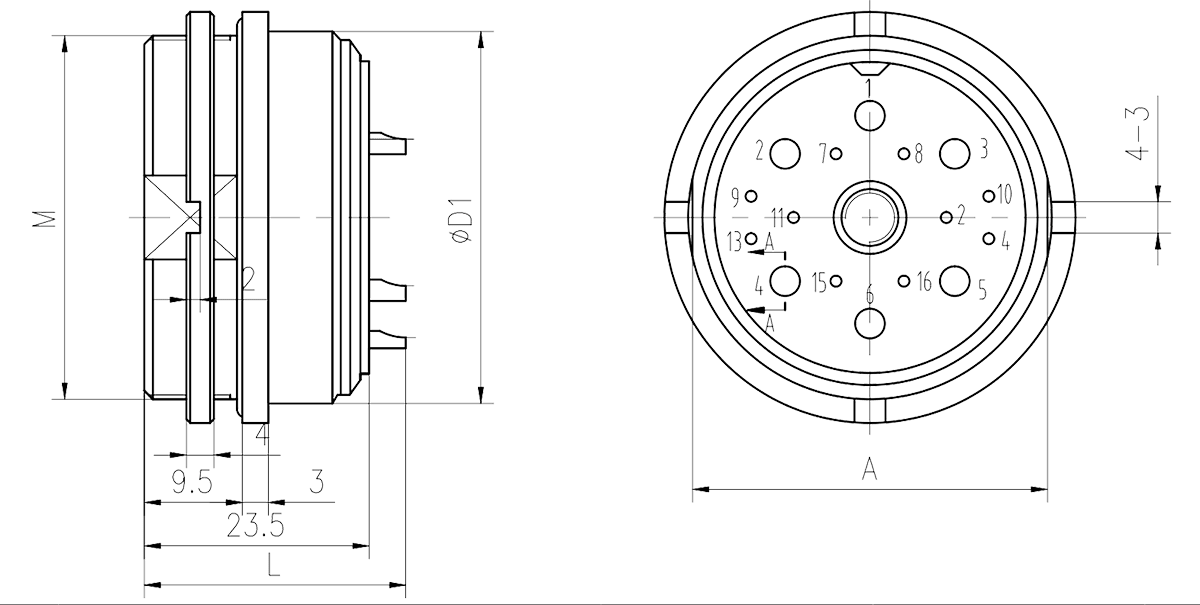

- Nut mounting socket

|

|||||

| Specification No. | L | D1 | M | A | |

| 18 | 1804

1805 |

28±2 | 33 | M32x1.5 | 30 |

| 1812 | 26.5±2 | ||||

| 24 | 2404

2404I 2414 |

26.5±2 | 43 | M42x1.5 | 40 |

| 2416 | 29±2 | ||||

| 2416I | 28±2 | ||||

| 2430

2438 2448 |

26.5±2 | ||||

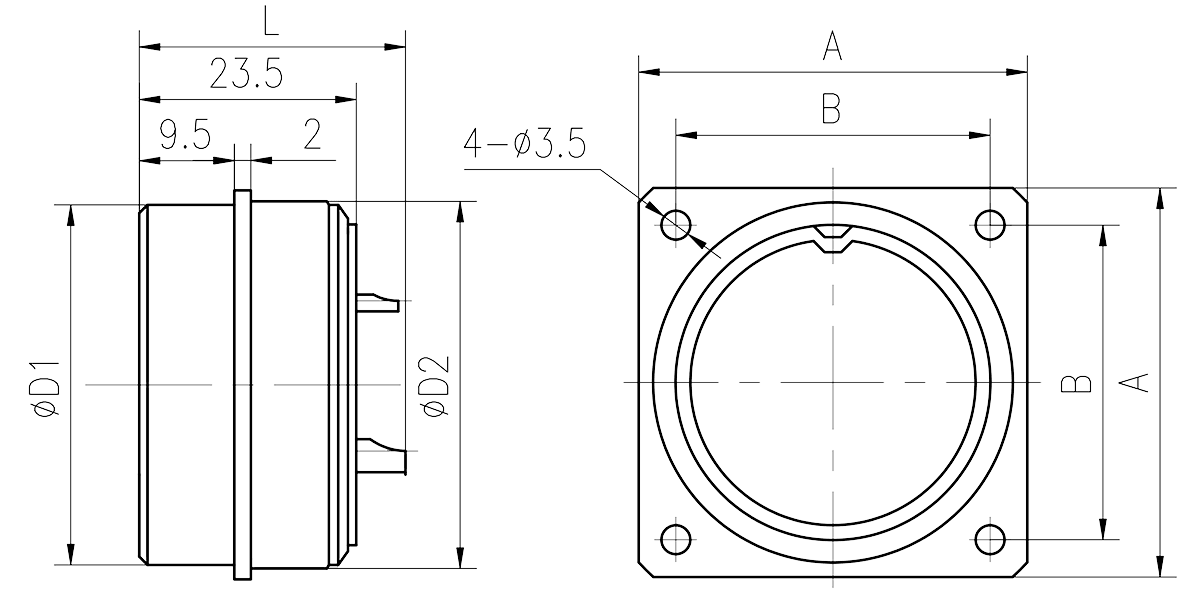

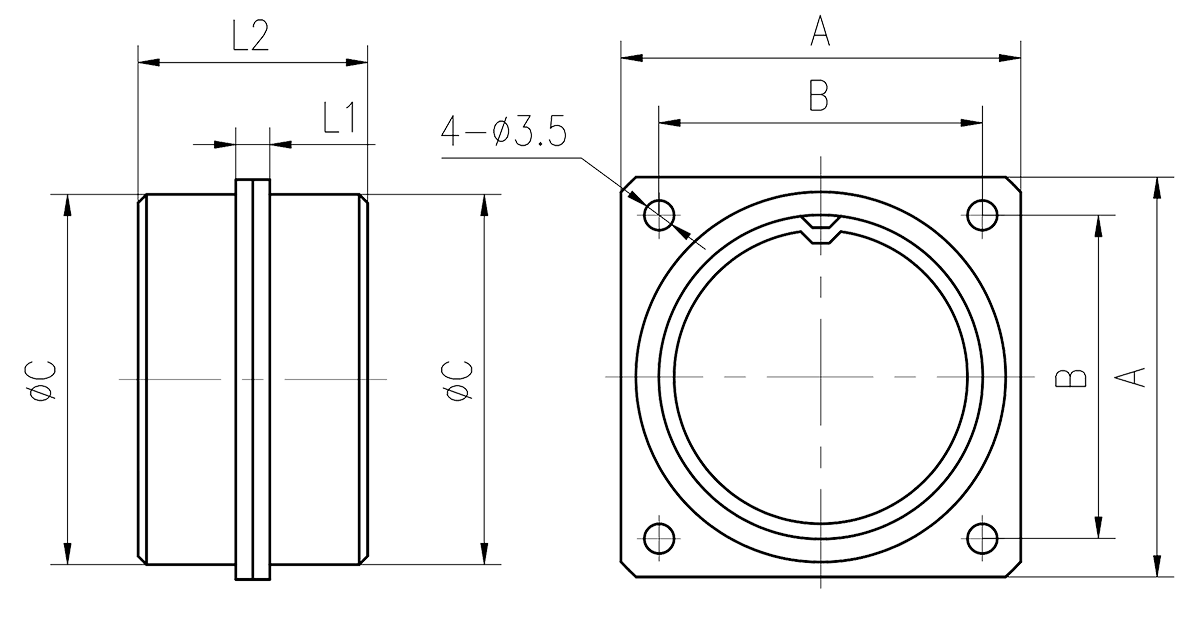

- Square Flange Receptacle

|

||||||

| Specification No. | D1 | D2 | L | A | B | |

| 18 | 1804

1805 |

32 | 33 | 28±2 | 38 | 30±0.125 |

| 1812 | 26.5±2 | |||||

| 24 | 2404

2404I 2414 |

42 | 43 | 26.5±2 | 47 | 38±0.125 |

| 2416 | 29±2 | |||||

| 2416I | 28±2 | |||||

|

2430 2438 2448 |

26.5±2 | |||||

| 30 | 45 | 46 | 29±2 | 52 | 41±0.125 | |

- Through wall Receptacle

|

||||||

| Specification No. | A | B | C | L1 | L2 | |

| 18 | 38 | 30±0.125 | 32 | 3 | 35±2 | |

| 24 | 2416

2416I 2438 |

47 | 38±0.125 | 42 | 3 | 35±2 |

| 30 | 3048I | 52 | 41 ±0.125 | 45 | 3 | 35±2 |

- Y16E-2416I Square Flange Glass Sealing Receptacle